Im Bereich der Fertigung sind Spritzguss und 3D-Druck die beiden vorherrschenden Verfahren zur Herstellung von Kunststoffteilen. Jedes Verfahren bietet einzigartige Vorteile und eignet sich für unterschiedliche Anwendungen

Continue readinglight weight construction parts

Lightweight construction parts - definition and application

Lightweight components, often key components of modern technologies, have had a significant impact on numerous industries in recent years. But what makes them light weight and how are they used in different sectors?

Definition

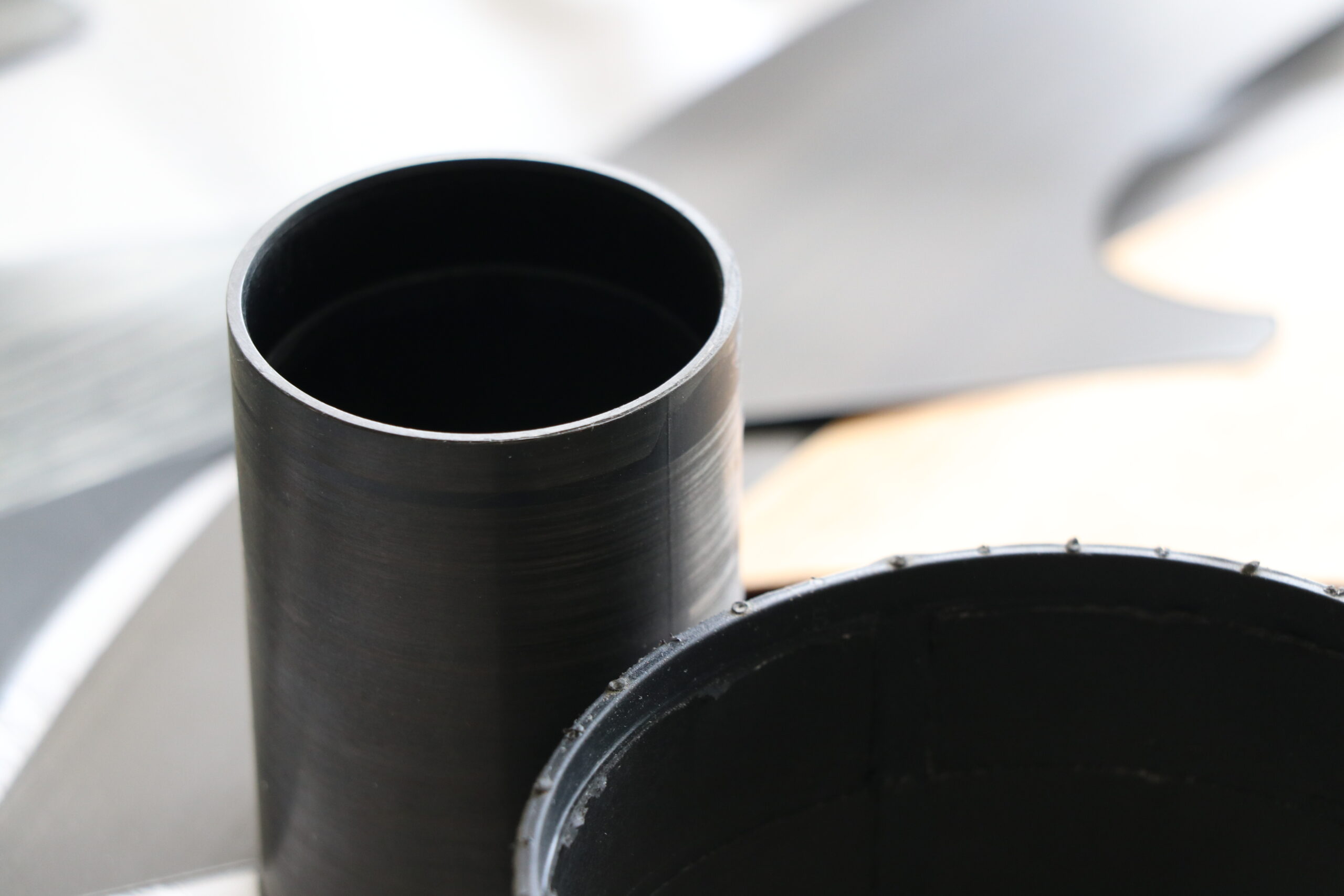

Lightweight components are components whose main characteristic is their low weight in relation to their mechanical strength and functionality. These components are usually made from materials that offer high strength at low weight. This enables improved performance and efficiency in a variety of applications.

Features of lightweight components

Low weight: The primary characteristic of lightweight components is their low weight compared to parts made of conventional materials such as metal.

High strength: Despite their low weight, lightweight components often have remarkable mechanical strength, which expands their range of applications.

Material diversity: Lightweight parts can be made from a variety of materials, including composites, aluminium alloys and advanced plastics. Thermoplastic composites show ideal properties in weight reduction as well as flexibility and stability.

Applications of lightweight construction in various industries:

In the aerospace industry, lightweight components are crucial for reducing the overall weight of aeroplanes and spacecraft. This leads to lower fuel consumption and a higher payload.

Lightweight construction plays a central role in the automotive industry, as lighter vehicles can increase driving dynamics, reduce fuel consumption and thus minimise environmental impact. Lightweight components can be found in body parts, engine components and chassis.

In energy technology, lightweight components are used in wind turbines and other renewable energy technologies to improve efficiency and durability.

Lightweight components are also used in medical technology, particularly in prostheses, implants and medical devices to increase patient comfort.

In the sports industry, lightweight components are used to improve the efficiency of athletes. svismold® thermoplastic composites show the advantages not only in weight reduction, but also in precise flexibility and ideal properties. One example of this is the FCS H4 surf fin. Other sporting goods can also benefit from the advantages.

In the construction industry, lightweight components are used for structural and façade components to increase the load-bearing capacity of buildings and optimise material consumption. The LongLife® Plus composite folding ruler is an ideal example of how a plastic folding rules can be reinforced and improved using svismold® technology. This has solved a long-standing problem with folding rules made from plastic: sagging over 2 metres.

Lightweight components are revolutionising various industries by offering a balanced combination of weight efficiency and strength. Their diverse applications not only contribute to more sustainable production, but also enable innovative solutions in technologies that impact our daily lives. In a world that is increasingly looking for environmentally friendly and efficient solutions, lightweight components play a crucial role in shaping the future.

Innovative Thermoplastic Composite Solutions

svismold®, a leading innovator in the development and production of tailored thermoplastic composites solutions, is set to showcase its cutting-edge offerings at the JEC World 2024 in Paris.

About svismold®: svismold® specializes in crafting high-end thermoplastic composites solutions designed for diverse applications, with a primary focus on the sports industry. The company is renowned for its commitment to innovation, precision engineering, and pushing the boundaries of what’s possible in composite materials.

JEC World 2024 Participation: svismold® is thrilled to announce its participation in the JEC World 2024, a major event for the composites industry. The company will be exhibiting under its brand, showing groundbreaking solutions that demonstrate the intersection of technology, performance, and sustainability. We will exhibit at the Composite united booth. You’ll find us in Hall 6, P24.

Key Highlights:

Tailored Solutions: svismold’s showcase will feature individualized thermoplastic composites solutions, tailored to meet the unique demands of the sports industry. These solutions are also adaptable for various technical applications.

Innovated Perfection: svismold® develops unique solutions and ensures highest quality. With FEM analysis the company test the possibilities and materials for perfectly fitting solutions.

Sustainability Focus: svismold® remains committed to sustainable practices. Learn about the company’s initiatives to minimize environmental impact while delivering top-notch performance in composite materials. We offer solutions with natural and sustainable materials for a better future.

Serial Production: svismold® offers not only unique parts tailored to our customer’s needs, but they also produce in serial. Therefore, material and time can be efficiently used.

At the heart of svismold’s showcase are its individually tailored thermoplastic composites solutions. These solutions, meticulously crafted to meet the unique demands of the customer, exemplify the company’s commitment to pushing the envelope in thermoplastic composite parts. From lightweight components to advanced structural elements, svismold’s offerings showcase a perfect blend of innovation and functionality.

Technical Versatility: While svismold® has carved a significant niche in the sports industry, the company’s technical expertise extends far beyond the athletic arena. The versatility of svismold’s solutions makes them applicable to a myriad of technical sectors. Whether it’s aerospace, automotive, or any other industry seeking advanced composite materials, svismold® has the expertise to address diverse challenges and opportunities.

Meet the svismold® Team: Visit svismold® at Booth P24 in Hall 6 during JEC World 2024 to engage with the team, explore product offerings, and discover how svismold’s innovative solutions can elevate your projects.

About svismold®: Since 1970 we are well established in the plastic industry as Kunststoffwerk AG. With the focus of thermoplastic composites projects the brand svismold® was established in 2018. The company offers unique and individual thermoplastic solutions. They work with partners such the IWK, Institute for Materials Technology and Plastics Processing for precise analysis to meet their customers needs. With a focus on innovation, precision engineering, and sustainability, svismold® is a trusted partner for companies seeking advanced solutions in composite materials.