Your reliable partner in the development and production of thermoplastic components

We develop and produce with you

As Kunststoffwerk AG, we have had experience with injection moulded parts for over 50 years. With svismold® we are revolutionising this proven method. Thermoplastic composite parts individually developed and produced; precisely tailored to your needs. We offer composite parts of the highest standards.

-stronger together-

Our

Technologies

A Success in Thermoplastic Composites Technology

This innovation project boosts growth.

Find out more about the Innosuisse innovation project with the University of Applied Sciences of Eastern Switzerland and the Iwk Institute for Materials Engineering and Plastics Processing.

Would you like to learn more? Contact us!

We are looking forward to discuss your idea with you – for free, no strings attached!

Our process

Feasibility Studies

Contact us!

We offer free feasibility studies.

In this step we discuss your idea and our possibilities to realise it.

Prototyping

In the next step, prototypes are manufactured. In this way, different materials and processes can be tested. The best solution becomes apparent and can be developed.

Production

When all tests have been completed and the results are satisfactory, production can finally begin.

We turn your idea into reality.

Contact us!

Or contact us via our social media

Frequently asked questions

Most frequent questions and answers

What types of thermoplastic composite parts does svismold® develop and produce?

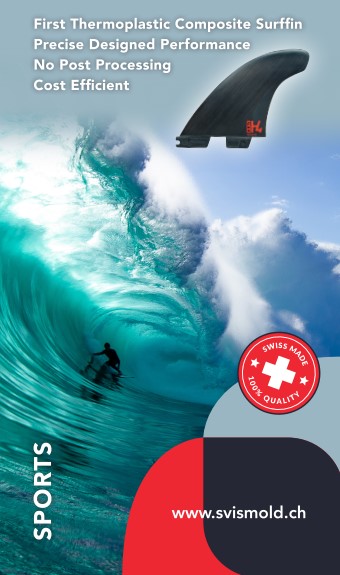

svismold® offers solutions in many different areas. From sporting goods to mechanical components and other technical parts, svismold® can develop and produce composite parts.

What are the advantages of thermoplastic composite parts compared to traditional materials such as, for example, metal?

Comparable to metal, weight reduction is one of the most important advantages. The components can be adapted very precisely to the stress and be flexible or rigid exactly where it is needed. The freedom of design is another feature that characterises the technology of svismold®.

In which industries are svismold® products mainly used?

Mainly svismold® experience in the field of sporting goods. We develop individual solutions. Our technology will also bring advantages in other technical areas.

What techniques are used by svismold® to meet customers' requirements.

svismold® develops injection moulding further. We think ahead.

With different techniques we achieve individual solutions in areas of sporting goods, mechanics and other technical areas. svismold® uses, among other things, tapes for reinforcement, natural materials for the design or foaming for weight reduction.

What is the process of working with svismold® when I have an idea or a project?

Please feel free to contact us! We discuss your idea with you and offer initial feasibility studies free of charge. Only if these are promising do we decide with you how to proceed. Which materials and which requirements are extremely important and much more, we will clarify with you.

What feasibility studies does svismold® carry out to assess the viability of a project?

So-called FEM studies show in what way we can support you. Various aspects are highlighted and worked out, which features are most important and what really matters to you. When the analysis are promising, together we can go all the way to the production of the finished parts.

Become part of our team!

We are looking for team members in engineering and production.

You are committed, motivated and love challenges?