Lightweight construction parts - definition and application

Lightweight components, often key components of modern technologies, have had a significant impact on numerous industries in recent years. But what makes them light weight and how are they used in different sectors?

Definition

Lightweight components are components whose main characteristic is their low weight in relation to their mechanical strength and functionality. These components are usually made from materials that offer high strength at low weight. This enables improved performance and efficiency in a variety of applications.

Features of lightweight components

Low weight: The primary characteristic of lightweight components is their low weight compared to parts made of conventional materials such as metal.

High strength: Despite their low weight, lightweight components often have remarkable mechanical strength, which expands their range of applications.

Material diversity: Lightweight parts can be made from a variety of materials, including composites, aluminium alloys and advanced plastics. Thermoplastic composites show ideal properties in weight reduction as well as flexibility and stability.

Applications of lightweight construction in various industries:

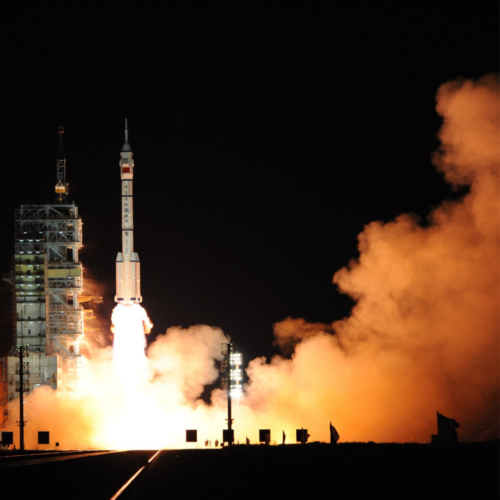

In the aerospace industry, lightweight components are crucial for reducing the overall weight of aeroplanes and spacecraft. This leads to lower fuel consumption and a higher payload.

Lightweight construction plays a central role in the automotive industry, as lighter vehicles can increase driving dynamics, reduce fuel consumption and thus minimise environmental impact. Lightweight components can be found in body parts, engine components and chassis.

In energy technology, lightweight components are used in wind turbines and other renewable energy technologies to improve efficiency and durability.

Lightweight components are also used in medical technology, particularly in prostheses, implants and medical devices to increase patient comfort.

In the sports industry, lightweight components are used to improve the efficiency of athletes. svismold® thermoplastic composites show the advantages not only in weight reduction, but also in precise flexibility and ideal properties. One example of this is the FCS H4 surf fin. Other sporting goods can also benefit from the advantages.

In the construction industry, lightweight components are used for structural and façade components to increase the load-bearing capacity of buildings and optimise material consumption. The LongLife® Plus composite folding ruler is an ideal example of how a plastic folding rules can be reinforced and improved using svismold® technology. This has solved a long-standing problem with folding rules made from plastic: sagging over 2 metres.

Lightweight components are revolutionising various industries by offering a balanced combination of weight efficiency and strength. Their diverse applications not only contribute to more sustainable production, but also enable innovative solutions in technologies that impact our daily lives. In a world that is increasingly looking for environmentally friendly and efficient solutions, lightweight components play a crucial role in shaping the future.