100% Automatic Camera Control

Constant high quality

The development phase took about 1 year

In one month svismold® could produce up to 6'000 fins

The Main Goal

Other than in many other projects, the leading goal was not to reduce the weight, but to garanty a constantly high quality throughout the production.

Many surf fins are made by hand so the stability, flexibility and other factors can vary immensely through the same series of fins.

FCS

FCS is an australian surf euipment supplier. They are well known for their well-equipped selection of surf fins.

Surf fins made by hand are never the same.

Each set will differ and each fin will differ from each other. Hence, surfer can never completely trust that the set they buy will work exactly like the one before. This is extremely frustrating, especially for proffessional sports.

FCS goal was to achieve constant high quality throughout the serial production. Asking a Swiss company was not an obvious choice. Switzerland and surfing? This country is rather known for its incredible chocolate and cheese. However, svismold’s combination of traditional injection molding with innovative technology seemed like the perfect choice. And svismold® did not disappoint.

Hand-made fins are not accurate enough

Each fin is different. The flex and speed, therefore, differ from one product to the other. Especially for professional use the users need to be able to expect the same high quality from each set.

We needed the perfect fin with a constant high quality.

FCS

Our solutions

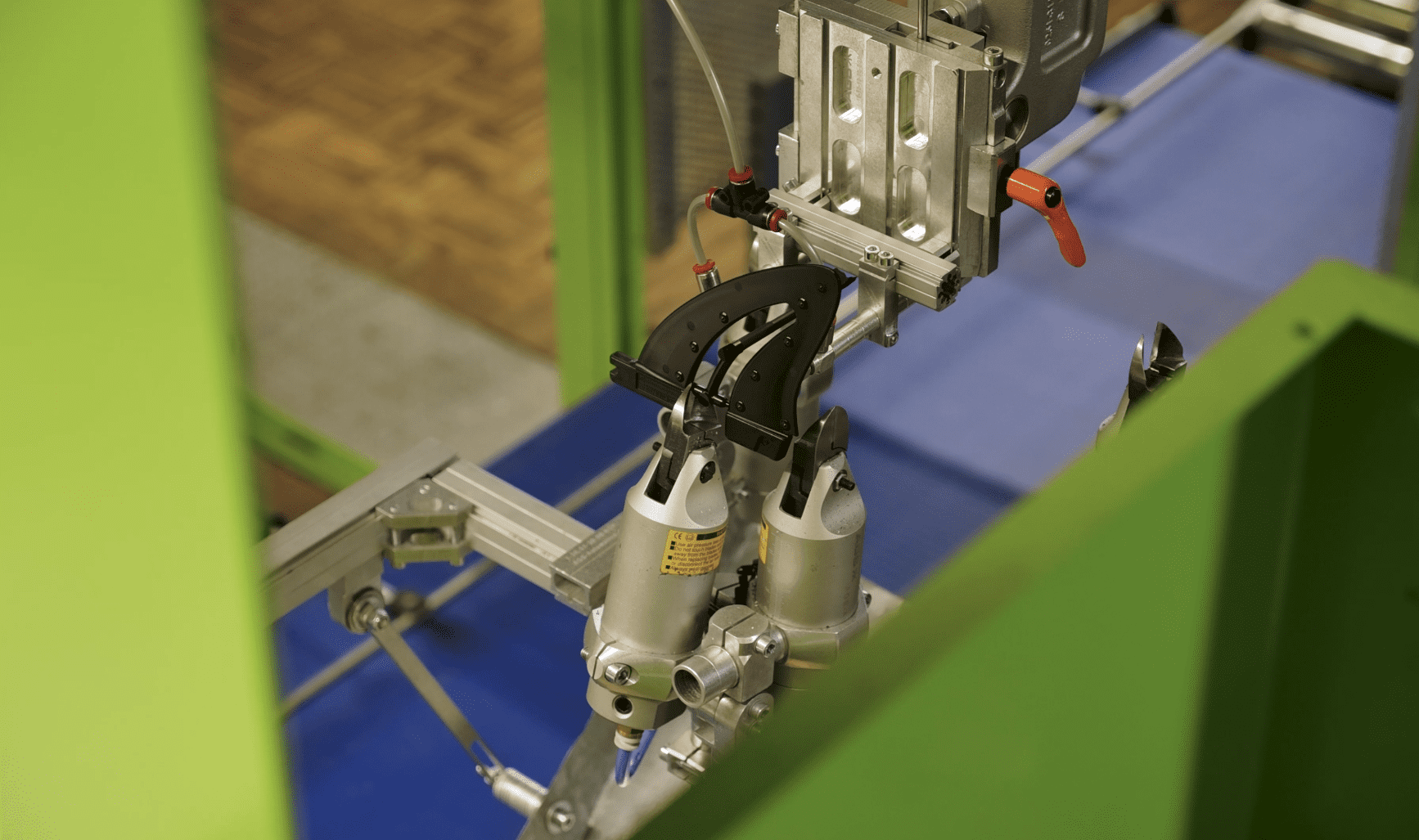

We used FEM analysis to figure out what the perfect fin would look like.

Flexibility and Strentgh

Within a fin there are different areas that need precise tape placement. Due to unidirectional tape it was possible to define the flexible edges but strong body of the high-end surf fin.

A surf fin needs to be strong enough to withstand the powerful water currents but also flexible enough to ensure a smooth maneuvering.

Hence, the choice of polypropylene as the injection plastic with inlain glass fibers strenghtend with carbon unidirectional tape was the perfect match.

The analyses have shown the best results with these materials.

Aerodynamic Form

The fin must glide through the water effortlessly. At the same time it must withstand enormous water currents. Moreover, the user needs to be able to control his board.

Flexibility and Strength

Flexibility and strength are extremely important for a surf fin to be controllable, fast and yet robust.

Material

The materials to make the perfect fin were crucial. We decided that the unidirectional carbon tape strengthened the body of the fin the best. Due to the precise placement of the fibers the flexibility and strength could be pinpointed to the areas where they were needed.

Smoothly Surfed through the Pandemic

Thanks to the high quality surf fins, svismold® did not face too many financial obsticles through the pandemic. With the helpful holding technique that was developed beforehand and the swisswide short support chains plus the automated processes order burglaries were completely outbalanced.

Used by Professionals

Professional surfers admit that the flex and curve of this H4 surf fin is phenomenal. In 2022 Filipe Toledo won his first World Surf Championship title with his set of FCS H4 Surf Fins.

Or contact us through our social media